with accurate bed leveling, the bed is sampled in a ACCURATE_BED_LEVELING_POINTSxACCURATE_BED_LEVELING_POINTS grid and least squares solution is calculated // Note: this feature occupies 10'206 byte 431 #define ACCURATE_BED_LEVELING_POINTS 4 399 #define Z_RAISE_BETWEEN_PROBINGS 10 //How much the extruder will be raised when traveling from between next probing points In my case, it is 【-20.35,11.75,0.3】, you can add it to the following settings.ģ89 #define X_PROBE_OFFSET_FROM_EXTRUDER 20.35 390 #define Y_PROBE_OFFSET_FROM_EXTRUDER -11.75ģ91 #define Z_PROBE_OFFSET_FROM_EXTRUDER -0.3ģ98 #define Z_RAISE_BEFORE_PROBING 100 //How much the extruder will be raised before traveling to the first probing point. When you hear the trigger of the endstop, you can get the coordinate on the LCD or on the Repetier host.

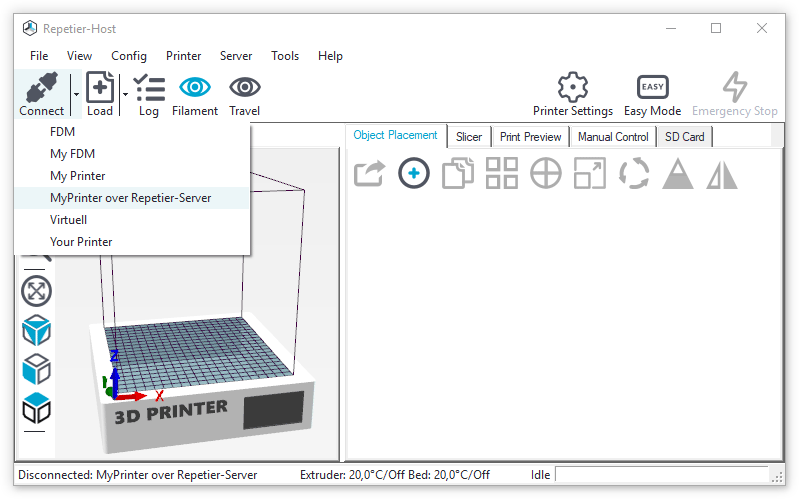

#Repetier server repetier host manual#

Manual y Move the print head down slowly, place the probe at the center of the print bed. You can calculate the Z_PROBE_OFFSET values with this procedure: these are the offsets to the probe relative to the extruder tip (Hotend - Probe), these values are very important, especially the Z_PROBE_OFFSET. these are the positions on the bed to do the probing,the probe positing should not be beyond the printable radius.ģ82 #define DELTA_PROBABLE_RADIUS (DELTA_PRINTABLE_RADIUS*0.6) 383 #define LEFT_PROBE_BED_POSITION -DELTA_PROBABLE_RADIUSģ84 #define RIGHT_PROBE_BED_POSITION DELTA_PROBABLE_RADIUSģ85 #define BACK_PROBE_BED_POSITION DELTA_PROBABLE_RADIUSģ86 #define FRONT_PROBE_BED_POSITION -DELTA_PROBABLE_RADIUS Travel limits after homing 365 #define X_MAX_POS DELTA_PRINTABLE_RADIUSģ66 #define X_MIN_POS -DELTA_PRINTABLE_RADIUSģ67 #define Y_MAX_POS DELTA_PRINTABLE_RADIUSģ68 #define Y_MIN_POS -DELTA_PRINTABLE_RADIUS 323 const bool Y_MIN_ENDSTOP_INVERTING = false // set to true to invert the logic of the endstop.ģ24 const bool Z_MIN_ENDSTOP_INVERTING = false // set to true to invert the logic of the endstop.ģ25 const bool X_MAX_ENDSTOP_INVERTING = false // set to true to invert the logic of the endstop.ģ26 const bool Y_MAX_ENDSTOP_INVERTING = false // set to true to invert the logic of the endstop.ģ27 const bool Z_MAX_ENDSTOP_INVERTING = false // set to true to invert the logic of the endstop.

use the Z-min, if you connect a mechanical endswitch between Com and NO pins, you do not have to change the setting for the Z-min, however, if you connect it between Com and NC pins, you should change false into true.ģ22 const bool X_MIN_ENDSTOP_INVERTING = false // set to true to invert the logic of the endstop. Print surface diameter/2 minus unreachable space (avoid collisions with vertical towers). Horizontal distance bridged by diagonal push rods when effector is centered.ġ22 #define DELTA_RADIU (DELTA_SMOOTH_ROD_OFFSET-DELTA_EFFECTOR_OFFSET-DELTA_CARRIAGE_OFFSET+ 2.0) =160-34-25+2 * To help you better understand the 4 values, you can refer to the scheme. and processor overload (too many expensive sqrt calls).ġ13 #define DELTA_SMOOTH_ROD_OFFSET 160.0 【2】ġ16 #define DELTA_EFFECTOR_OFFSET 34.0【3】ġ19 #define DELTA_CARRIAGE_OFFSET 25.0【4】 This is a trade-off between visible corners (not enough segments) Make delta curves from many straight lines (linear interpolation). Please pay close attention to the red numbers. #define DELTA and modify the values as below. Click Configuration.h and find out Delta Settings

#Repetier server repetier host download#

( If you do not have Arduino IDE, you can download here.)Ĥ. We have pre-loaded the firmware to GT2560 before shipping, but as this is a DIY printer, there may be some subtle difference between each printer, so you need to modify the firmware to fit your exact printer for better printing effect.ġ. (the distance between the nozzle and the print bed). You may have to adjust this for many times to keep the center point and its around point in one plain.

If the nozzle touches the around points but not the center point, you should increase the DELTA_RADIUS If the nozzle touches the center point but not the around points, you should reduce the DELTA_RADIUS Adjust the distance between the nozzle and the print surface, keep the center point and its around point in one plain.ġ22 #define DELTA_RADIUS (DELTA_SMOOTH_ROD_OFFSET-DELTA_EFFECTOR_OFFSET-DELTA_CARRIAGE_OFFSET+2.0) If the 3 numbers differ too much, you can manually move down the print head until the nozzle just hit the print bed, and screw the endstop screw tightly, if the screw has no room to adjust, you need to change the following setting later, record it. it is 2.7mm in my case.ģ)send G 0 X-43.3 Y-25 Z2, record the distance;e.g. it is 3mm in my case.Ģ)send command: G0 X43.3 Y-25 Z2, record the distance;e.g. 1)send command: G0 X0 Y50 Z2, record the distance;e.g.

0 kommentar(er)

0 kommentar(er)